2022-02-11|admin

Planetary reducer is a versatile industrial product that can reduce the speed of the motor while increasing the output torque. Often used in machine tools, automation, medical, printing and other industries. Let's take a simple case to see how the reducer should be selected. case

For example:

A uniform cylinder rotates in one direction around its axis, the rotation speed is 60 rpm, the total weight of the object is 300kg, the radius of the cylinder is 0.2 meters, the acceleration time is 1 second, and it works continuously for 2 hours after starting.

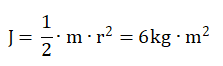

First calculate the moment of inertia when the cylinder rotates:

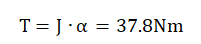

The acceleration time is 1 second, so the angular acceleration isα=6.283rad/s2

Maximum torque required when accelerating:

The motor chooses Siemens 1FT7042, the power is 850 watts, and the parameters are as follows:

|

Nominal output torque |

maximum torque |

Rated speed |

maximum speed |

Moment of inertia |

|

2.7Nm |

13Nm |

3000rpm |

6000rpm |

2.81kg |

Since the rotation speed is relatively slow and the power of the selected motor is relatively small, it is necessary to select a reducer with a two-stage speed ratio. Here, we choose Newcastle PLE60 series, and the reduction ratio is 40. The parameters of the reducer are as follows:

|

Torsional backlash |

Radial force |

Axial force |

Nominal output torque |

Max torque |

Average speed |

|

<12arcmin |

400N |

500N |

40N |

64Nm |

4500rpm |

Analyze the parameters:

1. Backhaul clearance. The equipment only makes continuous rotation in one direction, so it does not require high precision, and an economical reducer can be selected.

2. Radial and axial forces. Usually there will be a coupling connection between the reducer and the rotating object, and there will be a separate bearing seat for support, so there is no need to consider the radial and axial forces that the reducer can withstand.

3. Inertia ratio. Under this reduction ratio, the inertia ratio of the load and the motor is 13.35. Because the cylinder needs to continue to move for a long time after starting, the inertia ratio does not need to be controlled very small.

4. Speed. Under this reduction ratio, the final output speed of the motor is 2400rpm, which is less than the average input speed of the reducer, so the reducer will not heat up.

5. Rated torque. Although the rated torque of the reducer is only a little larger than the maximum torque required for the acceleration of the equipment, the acceleration time of the equipment is relatively short, and most of the time is moving at a uniform speed, so the actual torque that the reducer needs to bear is very small.

In summary, the reducer PLE60-40 meets the requirements for use.