PLN_01.jpg)

PLN_02.jpg)

PLN_03.jpg)

PLN_04.jpg)

PLN_01.jpg)

PLN_02.jpg)

PLN_03.jpg)

PLN_04.jpg)

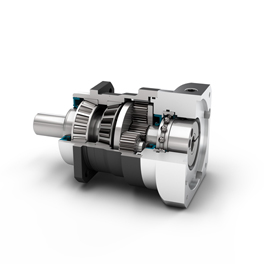

The perfectly sealed straight-toothed planetary gearbox delivers the maximum performance without ever losing the required stiffness.

Our straight-toothed precision planetary gearbox has been designed for the highest performance and torque. The prestressed tapered roller bearings in the PLN and the seal we have developed safeguard the optimal performance even against dust and water jets.

The PLN planetary gearbox is a highly hermetically sealed spur gear planetary gearbox that provides high efficiency without losing the necessary rigidity. This spur gear planetary gearbox is suitable for applications where high performance and torque are required. PLN is equipped with preloaded tapered roller bearings and our self-developed seals, which can effectively ensure the accuracy and tightness of the gearbox, prevent dust and splash water from entering the machine during operation, and can provide good performance.

Product description

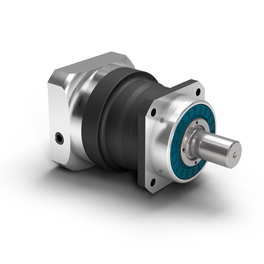

PLN planetary gearbox dust and splashing water will not affect the operation of this gearbox. Due to the fact that this gear unit is equipped with a radial shaft seal, it can also exert its excellent quality in harsh environmental conditions. The protection level of the PLN gearbox is IP65. With the design of the intelligent structure, the PLN is well protected during work. With this preloaded tapered roller bearing, the PLN is able to maintain its rigidity well and this gearbox is a reliable solution. The PLN is equipped with spur gears for high performance applications, and due to the intelligent design of this gearbox, the power density of this gearbox is better than that of conventional gearboxs.

The return clearance of the PLN gearbox is small, the normal model is 1-5 arc minutes, and the gearbox less than 1 arc minute can be customized. It is suitable for installation in any position, the input flange can be adapted to special motors, and the output shaft has a variety of styles, including spline, pin hole, pinion, and flange output. A square output flange is used, with an extra-long centering ring on the output end. The service life is 20000h, the working temperature is in the range of -25-90℃, and there are three ways to choose from standard, food grade and low temperature. The torsional stiffness of the gearbox is in the range of 3.4-224Nm, and the specific product data varies according to the selected model.

The detailed 3D model, the model parameters are clear and clear, and the technology provides model selection assistance.

Product advantages

Excellent rigidity under high loads

good sealing

Spur gears for high torque

Can be installed anywhere

Individually adjustable drive flange on the motor

Lubricated for life and therefore maintenance-free

Optional

return clearance

Various types of output shafts

Lubricate

Optimized tensioning system

Various types of drive flanges

installed pinion

Use

Lithium battery industry, coating machine industry, laser cutting, packaging and printing

Features

High sealing, high torque, high performance, high load

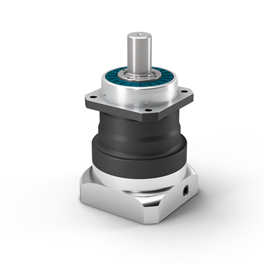

| Gearbox characteristics | PLN070 | PLN090 | PLN115 | PLN142 | PLN190 | P | |

| I | 3, 4, 5, 7, 8,10 | 1 | |||||

| I | 12,15,16,20,25,32,40,64,100 | 2 | |||||

| Service life |

h |

20.000 | |||||

| Service life at T2N×0.88 | h | 30.000 | |||||

| Efficiency at full load | % | 98/95 | |||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | |||||

| Protection class |

IP65 |

||||||

| Standard lubrication | 潤(rùn)滑油(終生潤(rùn)滑) | ||||||

| Food grade lubrication | 潤(rùn)滑油(終生潤(rùn)滑) | ||||||

| Low temperature lubrication | 潤(rùn)滑油(終生潤(rùn)滑) | ||||||

| Installation position | 任意 | ||||||

| Standard backlash | arcmin | <3-<5 | |||||

| Reduced backlash | arcmin | <2 | <1 | <1 | <1 | <1 | |

| Torsional stiffness | Nm/arcmin | 3.4-5.0 | 9.0-12.4 | 22.0-29.5 | 61.0-78.0 |

155.0-224.0 |

|

| Gearbox weight | kg | 2.0-2.6 | 3.3-4.3 | 6.5-9.0 | 16.0-22.0 | 33.4-49.6 | |

| Standard surface | 箱體:鋼 - 熱處理后氧化(黑色) | ||||||

| Running noise | dB/(A) | 60 | 62 | 65 | 70 | 74 | |

| Max bending moment based on the gearbox input flange | Nm | 18 | 38 | 80 | 180 | 300 | |

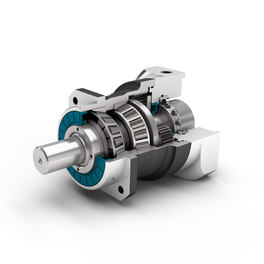

Nominal Output torque

| PLN070 | PLN090 | PLN115 | PLN142 | PLN190 | I | P |

| 45 | 100 | 230 | 450 | 1000 | 3 |

1 |

| 60 | 140 | 300 | 600 | 1300 | 4 | |

| 65 | 140 | 260 | 750 | 1600 | 5 | |

| 45 | 90 | 180 | 530 | 1300 | 7 | |

| 40 | 80 | 150 | 450 | 1000 | 8 | |

| 27 | 60 | 125 | 305 | 630 | 10 | |

| 68 | 110 | 250 | 780 | 1500 | 12 |

2 |

| 68 | 110 | 250 | 780 | 1500 | 15 | |

| 77 | 150 | 300 | 1000 | 1800 | 16 | |

| 77 | 150 | 300 | 1000 | 1800 | 20 | |

| 65 | 140 | 260 | 900 | 1800 | 25 | |

| 77 | 150 | 300 | 1000 | 1800 | 32 | |

| 65 | 140 | 260 | 900 | 1800 | 40 | |

| 40 | 80 | 150 | 450 | 1000 | 64 | |

| 27 | 60 | 125 | 305 | 630 | 100 |

Output shaft loads

| PLN070 | PLN090 | PLN115 | PLN142 | PLN190 | |

| Radial force for 20000 h |

3200 |

5500 | 6000 | 12500 | 21000 |

| Axial force for 20000 h | 4400 | 6400 | 8000 | 15000 | 21000 |

| Radial force for 30000 h | 3200 | 4800 | 5400 | 11400 | 18000 |

| Axial force for 30000 h | 3900 | 5700 | 7000 | 13200 | 18500 |

| Tilting moment for 20000 h | 191 | 383 | 488 | 1420 | 2535 |

| Tilting moment for 30000 h | 191 | 335 | 439 | 1295 | 2173 |

Geometry

| PLN070 | PLN090 | PLN115 | PLN142 | PLN190 | P | |

| Shaft diameter output | 16 | 22 | 32 | 40 | 55 | |

| Centering diameter output | 60 | 70 | 90 | 130 | 160 | |

| Flange cross section output |

70 |

80 | 110 | 142 | 190 | |

| Min. total lenght | 137.5 | 159.5 | 201 | 276 | 310.5 | 1 |

| 166.5 | 191.5 | 241 | 335 | 382.5 | 2 | |

| Shaft lenght output | 48 | 56 | 88 | 110 | 112 |

PLE_01.jpg)

PLQE_01.jpg)

PLPE_01.jpg)

PSFN_01.jpg)

PSFN_01.jpg)