PLFN_01.jpg)

PLFN_02.jpg)

PLFN_03.jpg)

PLFN_04.jpg)

PLFN_01.jpg)

PLFN_02.jpg)

PLFN_03.jpg)

PLFN_04.jpg)

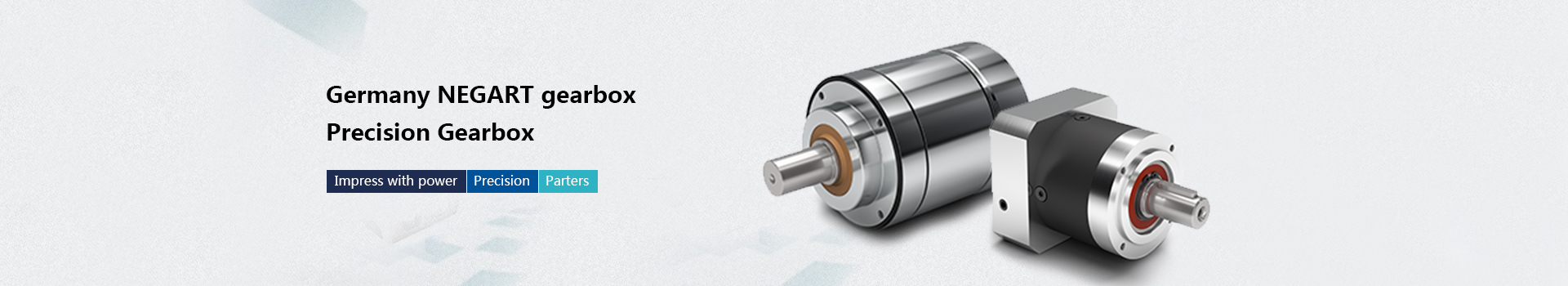

The precision planetary gearbox for maximum loads and the highest performance – fast and easy to install.

Our PLFN features a standardized flange interface for ease of installation. The straight-teeth precision planetary gearbox has been designed for the highest performance and torque. Its high tilting moment delivers the best performance even under the highest radial and axial forces.

PLFN planetary gearbox is a high-load planetary gearbox, and high performance, standardized flange output interface makes the installation of the gearbox more convenient. This spur gear planetary gearbox is suitable for use in applications that require high performance and torque. This gearbox has a high tilting moment, that is, high axial and radial forces, and also has excellent performance.

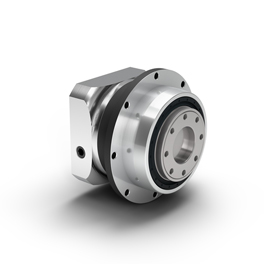

Product description

PLFN planetary gearbox is a straight-tooth flange output type planetary gearbox. The high-precision reduction gear has a standardized interface, and the installation of the drive components is very simple and safe. The optional positioning pin hole can provide additional protection for the safety of the gearbox. This gear unit has a high load capacity and because of the high tilting moment, the PLFN is robust and able to withstand high radial and axial forces, a technology for some high standard applications. With high torque, equipped with spur gears, it is suitable for high-efficiency applications, and because of the intelligent design, the torque of this gearbox is higher than that of ordinary gearboxs. The return clearance of this gearbox is small, 1-5 arc minutes, and can be customized to less than 1 arc minute. This gearbox can be installed in any position, the input flange can be adapted to a special motor, and the optimized moment of inertia locking system. Rated torque 27-1800Nm, radial force 2150-33000Nm, axial force 4300-15000Nm. With round extra-large output flange, ISO 9409 standard flange output shaft, planetary gearbox with pinion can be selected. The use of this gearbox is specified in 20000h, the working temperature range is about -25-90 °C, and there are three types of lubrication: food grade, low temperature, and standard.

Product advantages

Standardized flange interface

Spur gears for high torque

high load capacity

fully sealed

Small and exquisite

Can be installed anywhere

Optional

return clearance

Various types of output shafts

Lubricate

Optimized tensioning system

Various types of drive flanges

installed pinion

Use

Machine tools, food industry, laser cutting machines, trusses

Features

High load, high performance, easy installation, high torque

| Gearbox characteristics | PLFN064 | PLFN090 | PLFN110 | PLFN140 | PLFN200 | P | |

| Reduer | 4, 5, 7, 8,10 | 1 | |||||

| Reduer | 16,20,25,32,40,50,64,100 | 2 | |||||

| Service life |

h |

20.000 | |||||

| Service life at T2N×0.88 | h | 30.000 | |||||

| Efficiency at full load | % | 97/96 | |||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | |||||

| Protection class |

IP65 |

||||||

| Standard lubrication | Grease (lifetime lubrication) | ||||||

| Food grade lubrication | Grease (lifetime lubrication) | ||||||

| Low temperature lubrication | Grease (lifetime lubrication) | ||||||

| Installation position | Any | ||||||

| Standard backlash | arcmin | <3-<5 | |||||

| Reduced backlash | arcmin | <2 | <1 | <1 | <1 | <1 | |

| Torsional stiffness | Nm/arcmin | 7.6-14.8 | 18.5-40.5 | 58.0-92.0 | 156.0-264.0 |

330.0-656.0 |

|

| Gearbox weight | kg | 1.4-1.9 | 2.9-3.5 | 5.0-6.3 | 12.9-15.6 | 37.0-45.9 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | ||||||

| Running noise | dB/(A) | 60 | 62 | 65 | 70 | 74 | |

| Max bending moment based on the gearbox input flange | Nm | 18 | 18/38 | 38/80 | 80/180 | 180/300 | |

Nominal Output torque

| PLFN064 | PLFN090 | PLFN110 | PLFN140 | PLFN200 | I | P |

|

60 |

140 | 300 | 600 | 1300 | 4 |

1 |

| 65 | 140 | 260 | 750 | 1600 | 5 | |

| 45 | 90 | 180 | 530 | 1300 | 7 | |

| 40 | 80 | 150 | 450 | 1000 | 8 | |

| 27 | 60 | 125 | 305 | 630 | 10 | |

| 77 | 150 | 300 | 1000 | 1800 | 16 |

2 |

| 77 | 150 | 300 | 1000 | 1800 | 20 | |

| 65 | 140 | 260 | 900 | 1800 | 25 | |

| 77 | 150 | 300 | 600 | 1800 | 32 | |

| 65 | 140 | 260 | 750 | 1800 | 40 | |

| 65 | 130 | 260 | 620 | 1525 | 50 | |

| 40 | 80 | 150 | 450 | 1000 | 64 | |

| 27 | 60 | 125 | 305 | 630 | 100 |

Output shaft loads

| PLFN064 | PLFN090 | PLFN110 | PLFN140 | PLFN200 | |

| Radial force for 20000 h | 2150 | 3950 | 4900 | 12000 | 33000 |

| Axial force for 20000 h | 4300 | 8200 | 9500 | 8500 | 15000 |

| Radial force for 30000 h | 1900 | 3500 | 4350 | 11000 | 29500 |

| Axial force for 30000 h | 3800 | 7200 | 8400 | 7500 | 13500 |

| Tilting moment for 20000 h | 132 | 326 | 475 | 1219 | 4957 |

| Tilting moment for 30000 h | 117 | 289 | 422 | 1117 | 4431 |

幾何尺寸

| PLFN064 | PLFN090 | PLFN110 | PLFN140 | PLFN200 | P | |

| Pitch circle diameter output shaft | 31.5 | 50 | 63 | 80 | 125 | |

| Centering diameter output flange | 64 | 90 | 110 | 140 | 200 | |

| Flange diameter output | 86 | 118 | 145 | 179 | 247 | |

| Min. total lenght | 71 | 89 | 108 | 157 | 212.5 | 1 |

| 99.5 | 111 | 130 | 187.5 | 264 | 2 | |

| Output flange length | 19.5 | 30 | 29 | 38 | 50 |

PLE_01.jpg)

PLQE_01.jpg)

PLPE_01.jpg)

PSFN_01.jpg)

PSFN_01.jpg)