Industry news|2022-02-18| admin

The function of the drum gear coupling

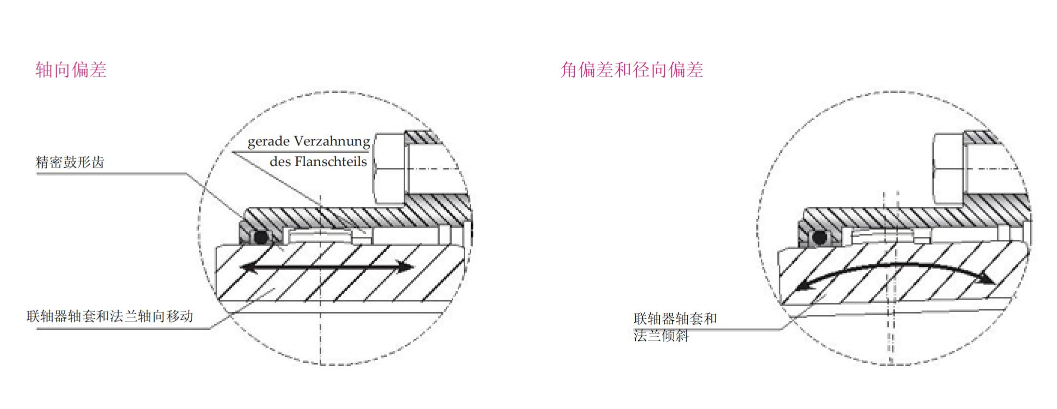

The tight combination of the coupling sleeve and the intermediate flange makes the coupling low in backlash and high in torque transmission rigidity. At the same time, it can compensate for radial, axial and angular assembly deviations.

The drum-shaped structure of the gears allows long service life and no assembly errors.

Recommended Grease

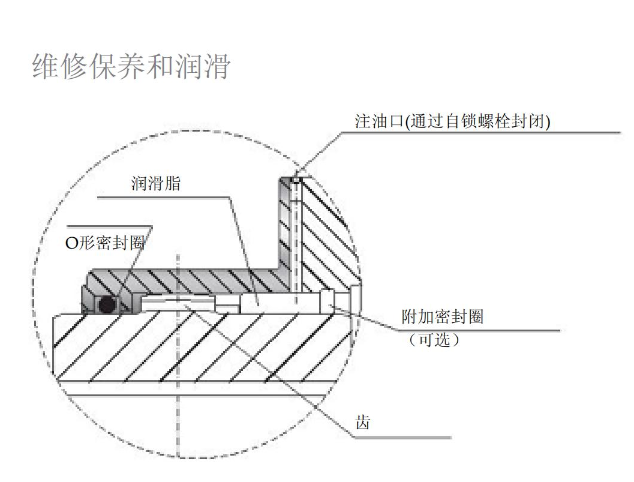

Correct lubrication is very important for the service life of the coupling. In order to prolong the lubrication cycle, it can be sealed. High-performance lubricating oil is recommended.

| normal speed and load | high speed and load | ||

| 嘉實(shí)多 | lmpervia MDX | 加德士 | Coupling Grease |

| 埃索 | Fibrax 370 | 克魯勃 | Klüberplex GE 11-680 |

| 克魯勃 | Klüberplex GE 11-680 | 美孚 | Mobilux XTC |

| 美孚 | Mobilux EPO | 殼牌 | Albida GC1 |

| 殼牌 |

Alvania grease EP R-O or ER 1 |

德士古 | Coupling Grease |

| 道達(dá)爾 | Specis EPG | ||

R+W BZ1 and BZA drum gear coupling, this coupling has keyway installation, the coupling material is composed of polished high-strength steel, the sleeve has keyway installation or high-precision cylindrical hole for interference fit, Optional DIN916 retaining nut can be used to lock to the shaft key.

This type of coupling has a bushing that can be extended on one or both ends, which facilitates replacement of existing gears and is more space-friendly; with brake disc, which can be custom-sized for holding or emergency stop; with one or both ends Reverse shaft sleeve, the shaft end distance is slightly increased, the shaft end can achieve the most ideal torque transmission, and the coupling has a longer service life.